Max Rotter letter to James R. Harris - May 25, 1917

Transcript

COMPANY CORRESPONDENCE SUBJECT: TRANSACTIONS WITH SULZER BROS. St. Louis, [Missouri], May 25, 1917 Mr. J.R. Harris, V.P. & Gen. Mgr. The following is a general statement of our transactions with Sulzer Bros. in engineering matters:- PERIODICAL COMMUNICATIONS Early in 1913, it was agreed between Sulzers and us that each write to the other a letter of general technical information, every two months. Such letters were to relate, in particular, experiences with all types of Diesel Engines, troubles and their remedies, and contemplated improvements and the reasons for same. Sulzers carried out this agreement quite consistently until the war interrupted free communication, and reduced their staff. We did not carry out the agreement, except to a very limited degree; first, because we had only type "A" engines in operation, and but few engines of other makes were running in this country; and, second, because we had only a very limited engineering staff in process of organization, and were overburdened with work in getting a new plant under way constructing new types of engines. Later the interruption of free communication caused us to leave the matter in abseyance. STATIONARY ENGINES -- FOUR CYCLE Sulzers have provided us with such drawings as we requested, until the beginning of the war. They have answered, with reasonable promptness, such questions as we have asked. In July, 1914, we forwarded to Sulzers a complete set of detailed prints of our 4-B-125 engine; although the manufacture of the first engine had only commenced, and the engine was not ready for shop tests until November, 1914. These prints were received by Sulzers in November, 1914. In March, 1915, we forwarded to Sulzers complete sets of detailed prints of our 4-B-30 and 4-B-40 engines. These were received by Sulzers in April, 1915. The prints were sent Sulzers put them in possession of the details of construction of our full line of four cycle stationary engines, as the intermediate sizes would differ only in dimensions; and we furnished them tabulations of these sizes for each of our five standard engines. We requested comments on our tabulated dimensions, as also on the details of our designs; but did not receive such comments, due, undoubtedly, to the war conditions. Sulzers have not communicated to us all improvements and corrections that they have, from time to time, made on their stationary engines, (for example, the correction of piston cooling, and the injection air pressure regulation to suit variable loads); nor have we communicated to Sulzers all improvements and corrections that we have, from time to time, made on our type "B" engines, (for example, increasing the capacity of the compressor of engine 4-B-30).

Transcript

COMPANY CORRESPONDENCE SUBJECT: TRANSACTIONS WITH SULZER BROS. [page 2] STATIONARY ENGINES --TWO CYCLE The latest prints we have received from Sulzers are the details of their 4-Z-200. These were forwarded to us in September, 1913, and received by us in November, 1913. In July 1914 we cabled for latest designs, and were informed by Sulzers that they had nothing later than those above mentioned. In August, 1915, we cabled Sulzers that we were designing large two-cycle stationary engines; we did not specifically ask for prints, but only for advice regarding number of cylinders. Sulzers answered our question; but did not state whether their designs had been modified since 1913. In October, 1916, we cabled Sulzers, through the Swiss Legation, in Washington, asking them to mail us general drawings of their latest design of 4-Z-250, with a description of suggested improvements. We did not receive a reply and assumed that it was due to the conditions mentioned in a letter they had written to us earlier in the year, in which letter they stated, with reference to other drawings we had asked for, "considering the present difficulties and risks, we would propose to send you these drawings at a more convenient time". In November, 1916, when writing to Sulzers with reference to our suggestion that one of their engineers pay us a visit, we stated that, in addition to technical information to be brought by their engineer, we desired their latest designs of two-cycle stationary engines of Z-200 or Z-250 size. We have not heard anything from them about this. Should we find it advisable to commence designs of two-cycle stationary engines, we would have to be guided by designs sent us over three years ago, and such suggestions as Sulzer's engineer (Mr.Kilchenmann), who arrived here in April, would make. MARINE ENGINES -- COMMERICAL Our condition, with reference to these, is similar to that with reference to stationary two-cycle engines. The latest drawings we have are those of the "Monte Penedo" engines, which were forwarded to us in August, 1913, and received by us in October, 1913. We have not, however, specifically asked Sulzers for later drawings; except in September, 1916, when inviting them to send over one of their best engineers. SUBMARINE ENGINES -- "U 32

Transcript

COMPANY CORRESPONDENCE SUBJECT: TRANSACTIONS WITH SULZER BROS. [page 3] would suggest, as we desired to tender on duplicates. We received the prints in September, 1913; and a letter in which Sulzers suggested only a speed reduction to 420 revolutions per minute, a change in the bedplate, and more room around the engines. In May 1914, we closed a contract with the new Lake Company, for six 600 horsepower engines, which were to be duplicates of Sulzers' "U-32", except that the speed was to be reduced to 375 revolutions per minute, and that certain modifications were to be made for the purpose of increasing the accessibility of the parts and facilitating dis-assembling and re-assembling in the boat. While we were negotiating with Lake, for these engines, we wrote to the Sulzer, on April 18th, 1914; stating, in general, the purpose of such changes as we might have to make, and that we might wish to purchase some of the castings from Sulzers. To this letter we received a reply, date May 18th 1914, that there appeared to be no difficulty about making the changes; that Sulzer proposed, in future, to make this size of engine with the cylinder heads cast integral with the cylinders, instead of separate as in the case of the "U-32"; and that, owing to the extreme pressure of work in their marine drawing office they were not in a position to undertake the reconstruction of these engines, such as would be desirable if an order should be placed, but intended to take up this work as soon as an opportunity presented itself. On June 11, 1914 we wrote to Sulzers, in full detail, exactly what changes we were considering making to their "U-32" designs; and asking for their views and their advices as to what changes we should make, to improve these engines. To this letter we received a reply, dated June 26, 1914, to the effect that although Sulzers had not constructed submarine engines since the two for the "G-3", they had been studying the question, on the basis of experiences with these and other marine engines, and, were they to receive and order at that time, would make very material alterations and improvements; and they advised that we send one of our designers to Winterthur to confer with them regarding these. As we had, at that time, only seven designers, only two of whom had been with us over three months and were familiar with and busy on our stationary engines, we at once (on July 13, 1914) cabled Sulzers that, on account of the imperative necessity of immediately submitting , to the Bureau, the general drawings which are required to confirm a Naval contract, we could not send an engineer; and asking whether they could let their best engineer, on this class of work, come here, at our expense, to bring us drawings, and technical and cost information. Not receiving a reply, we cabled again on July 15, 1914; and immediately received a cabled reply that Sulzers could not spare any of their staff and suggesting that we send two of our engineers to Winterthur, to make the principal drawings under the supervision of their staff. On July 27, 1914, Mr. Verhey, who was the best of the designers we could spare for this work, sailed form New York. While he was on the ocean, the war broke out, and it took him three weeks to reach Winterthur. It became evident that, on account of the military duties of Sulzers engineers, Mr. Verhey's work would require longer than we had estimated; and that on account of the very strict government control, it might, in the end, be impossible for him to bring any actual drawings with him; in fact, it seemed not unlikely that he would be indefinitely interned in Switzerland. Meanwhile, we were under the necessity of showing some progress and of organizing a force of designers to work up the data Mr. Verhey would bring here; or, if it came to the worst, to make the entire

Transcript

COMPANY CORRESPONDENCE SUBJECT: TRANSACTIONS WITH SULZER BROS. [page 4] designs. We, therefore, started on designs, on the basis of the information then in our hands. We had planned to have a second engineer join Mr. Verhey in Winterthur; but the war prevented this. On the day after Mr. Verhey had sailed, we received Sulzers' letter of July 17, 1914, answering ours of June 11, 1914; suggesting and explaining changes they advised; and accompanied by a general arrangement print, showing the engine as modified. The latter print showed the overall length of the engine, from the forward face of the flywheel, to be 19-ft. 3-ins. We answered this letter on August 19, 1914; making various comments and calling attention to the fact that the engine, in order to go into the available space, must be 17 inches shorter than shown. This matter had not been previously discussed, as we had expected the engines to be duplicates of the G-3. On September 24, 1914, we wrote to Sulzers, explaining why it had become necessary to "act upon our own initiative considerably more than we would have desired"; also that, on account of the necessity of obtaining the Bureau's approval of details, it would be inadvisable for the full detail drawings to be made in Winterthur. On October 3, 1914, we mailed, to Sulzers, blueprints of a number of preliminary arrangement drawings we had made, together with explanations and technical data; showing how we were considering building the engines, should we fail to receive data from Sulzers in reasonable time. These drawings substantially followed the construction shown by Sulzers' latest print (which accompanied their letter of July 17, 1917); but with modifications, such as a tandem scavenging pump, made necessary by space and accessibility demands. In the strictly

Transcript

COMPANY CORRESPONDENCE SUBJECT: TRANSACTIONS WITH SULZER BROS. [page 5] CRANKCASE:- Sulzers' cylinder supports adopted; but covers were made for each individual cylinder, with bronze frames and sheet steel panels, and with gaskets as used in our type "B" engines, because we considered this neater, tighter, and affording readier accessibility to each piston and its parts (In our later designs we have improved on this only by making the gasket surfaces all in one plane). CRANKSHAFT:-Cranks set as recommended by Sulzers. No. 4 crank made of special design; because length of shaft had to be reduced, on account of Bureau's refusal to approve rotary oil pumps below floor. WORKING PISTON:-No drawing was furnished, and we were mainly guided by Sulzers' "U-32". We omitted the nickel plate in the piston top, because its use would infringe a U.S. patent, and there seemed to be a difference of opinion among Sulzers

Transcript

COMPANY CORRESPONDENCE SUBJECT: TRANSACTIONS WITH SULZER BROS. [page 6] were materially changed, and valve levers were used. The reasons for these changes were the fact that the Bureau insisted upon enclosed cam-haft and cams running in oil, and that we brought the operating levers into a more convenient position for an operator of average height. STARTING VALVES:- Sulzers' double starting valves were used, with minor modifications which suggested themselves as the details were developed. FUEL VALVES:-These are substantially as designed by Sulzers. Some details of construction were modified on the basis of advices we had received from Sulzers; and others on the basis of our experience with broken fuel needles, and to facilitate dis-assembling; but none of these changes would affect the actual operation of the valves. INTERLOCKING DEVICES:- These were re-designed by us, in a form which appeared to us preferable to and cheaper than that laid out by Sulzers. The results accomplished are the same. Sulzers' have since applied for a German patent on our design. SCAVENGING VALVES:- In these we followed Sulzers' general scheme, with the following modifications:- The valves were made so that, in case of breakage of the valve-closing spring, the overpressure in the working cylinder would hold the valve on its seat, and prevent a blow-back into the scavenging receiver. The closing springs were arranged above, instead of below, the valves, making them visible and accessible while the engine is in operation and without removing the coverplates of the receiver. FUEL PUMP:- This we have designed entirely according to our own experience, incorporating in it the features which have long given satisfaction on the fuel pumps of our type "A" engines namely:- all mechanism outside and visible; suction valves so arranged that the delivery of air into the engine fuel pipes is impossible. We have also provided each plunger with a separate suction channel, so that any individual fuel valve may be primed without stopping the engine. LUBRICATING PUMP:- This we have designed entirely according to our own judgment, incorporating features which we consider to be improvements, namely:- means for temporarily furnishing an excessive supply of lubricating oil to the working cylinder, combined with means for entirely shutting off the supply, all without changing the adjustments for the regular supply; and a visibly supply, separately adjustable for each cylinder. WATER AND OIL PUMPS: Sulzers

Transcript

COMPANY CORRESPONDENCE SUBJECT: TRANSACTIONS WITH SULZER BROS. [page 7] specified, and neither Sulzers nor we expected much severe requirements; although the general clauses of Navy specifications seem to enable the Bureau to enforce the demand, inasmuch as no definite figures were stated. Our coolers were substantially of the same design as Sulzers; but the proportions are different, in that we have, per engine, two and one quarter times as much cooling surface, with about one third of the oil velocity through the tubes; and we now understand from Sulzers that our increase in cooling area is not, as we estimated, sufficient to make up for the reduction in efficiency due to the reduced oil velocity. Also, Sulzers did not figure on such temperature differences as now demanded by the Bureau. AIR COMPRESSOR PISTONS:- Sulzers' design substantially followed; excepting that we made the high pressure piston a separate casting from the low pressure, because we were having trouble in obtaining sound castings of combined pistons for our type "B" compressors, and the separation of the pistons facilitated dis-assembly in the boat. AIR COMPRESSOR CYLINDERS:- Sulzers' design substantially followed. (On account of trouble from moisture in the cylinders, due to too energetic cooling of same, we intend, in future, to separate the air coolers from the cylinders, so as to obtain greater cooling effect in the former than in the latter). AIR COMPRESSOR VALVES:- Sulzers' design of high pressure valves substantially followed. We entirely re-designed to the intermediate and low pressure valves and seats, because we were experiencing much trouble with ring valves, as advocated by Sulzers, in our type "B" compressor. (We are now informed that Sulzers have overcome these trouble by the use of Chrome Nickel Steel, and we purpose to adopt the design and material.) AIR COOLERS:- Sulzers' design substantially followed; but, due to the use of American standard tubes, our average cooling surface is about 35 per cent greater than the minimum recommended by Sulzers, and the air velocity through the tubes about 20 per cent lower than the minimum recommended by Sulzers at that time. We found it necessary to add a small auxiliary air cooler. (We understand that Sulzers now recommend cooling surfaces about 75 per cent greater, and air velocities about 60 per cent lower than they did at that time.) SCAVENGING PUMP PISTONS:- Sulzers' design substantially followed; except that we made the upper and lower pistons of the same diameter, and changed some details to facilitate the removal of the lower piston from below. SCAVENGING PUMP CYLINDERS:- These we re-designed; because, at that time we were afraid of trying to get the complete casting, consisting of both cylinders and their valve chest, in one piece; and we wished to avoid making right and left hand cylinders. (Since our foundry has become broken in on this work, we would re-consider our decision of that time.) SCAVENGING PUMP VALVE GEARS:- These we entirely re-designed; because, using an enclosed camshaft, we did not find means which satisfied us, to drive the valve from the camshaft, without either having moving parts exposed in the gangway, or encroaching too much upon the gangway space by enclosing such parts. These considerations drove us into an expensive construction, which we would try to avoid, were we to build more of these engines.

Transcript

COMPANY CORRESPONDENCE SUBJECT: TRANSACTIONS WITH SULZER BROS. [page 8] FLYWHEEL HOUSING:- We entirely housed in the flywheel, as this was demanded. It was, also, necessary for our housing to support the clutch housing and the clutch-operating mechanism. These parts are considerably more expensive than the arrangement suggested by Sulzers; but we saw no simpler method for accomplishing the desired results. (We have, since then, somewhat simplified the housing and barring gears; but cannot adopt Sulzers

Transcript

COMPANY CORRESPONDENCE SUBJECT: TRANSACTIONS WITH SULZER BROS. [page 9] assistance from Sulzers. In September, 1915, we informed Sulzers that we were being forced to bid on four cycle submarine engines, in order to receive consideration; and we gave them the general technical data we contemplated using in designing these engines. We also asked for certain specific data. This letter was replied to in October, 1915, with Sulzers approval of our general data, and their answers to the specific questions we had asked. In January, 1916, we wrote Sulzers that this matter was becoming active, and gave them farther general data as to our intentions, - among others, that we contemplated making the cylinders with separate heads, and with the jacket and liner cast in one piece; - and stated that we would be grateful to their comments. This letter was acknowledged by Sulzers, in February, 1916, with the brief statement that they were generally in agreement with our assumptions, and the suggestion that we send them the principal drawings we had made for these four cycle engines. At that time we had not made anything but general outlines for the guidance of Lake Company. In January, 1916, we wrote Sulzers a second letter, supplementing that of a few days before, stating that we had closed contracts for twelve of the four cycle engines, giving additional data of our intentions, and suggesting our desire for their comments. No farther correspondence occurred, until, in September 1916, we sent Sulzers a very full letter, describing the engines in detail as we were designing them, and enclosing prints showing the construction of working cylinder and head we were planning to use. We understand, from Mr. Kilchermann, that this letter and these prints were received by Sulzers, and that he believed they had been replied to; but we have not received a reply. Upon Mr. Kilchermann's arrival here, last month, we submitted to him a complete file of detail prints of these engines, and he is preparing written comments on same; but these are not yet in our hands. SUBMARINE ENGINES 6-M-150--(FOR SUBMARINE "S"). Contract for two of these engines was closed in December, 1916. No correspondence has taken place between Sulzers and our engineering department; but Sulzers we advised of our receipt of this order, by our regular monthly report. We have submitted to Mr. Kilchermann, and sent copy of same to Sulzers, a detailed statement of the technical data on which we were basing our designs; and have received his comments and suggestions. We are, also, obtaining his suggestions and advice on the more important engine parts, (i.e. working cylinders, heads, and pistons; compressor; scavenging pump; and crankshaft) the designing of which is now proceeding in our office. SUBMARINE ENGINES -- GENERAL As we have been criticized as doing too much "engineering" on this type of engine, instead of obtaining Sulzers' designs and following these in detail, the following conditions may serve to explain our reasons. (1) We have Sulzers' own statement, in their letter of January 26, 1916, in response to our request for certain stationary engine drawings, that they

Transcript

COMPANY CORRESPONDENCE SUBJECT: TRANSACTIONS WITH SULZER BROS. [page 10] would not hesitate to send us drawing if the conditions of mail service were normal; but considering the existing difficulties and risks, proposed to send them at a more convenient time. This statement, together with a previous one to the effect that their engineering offices were badly handicapped due to military service, caused us to refrain from making direct requests. (2) We were not aware that Sulzers were building any submarine engines. The latest information we had, until Mr. Kilchermann arrived last month, was that the G-3 engines were the last Sulzers had built; other than an experimental 350 horsepower cylinder, of which we asked for drawings and data, but they answered that they preferred not to give us these until their experiments were completed. (3) Sulzers were regularly informed, either through our engineering department or our monthly reports, of submarine engines which we were tendering on, and contracts received by us for such engines; but they failed to notify us that they were building similar engines, and they did not, therefore, afford us the opportunity of specifically in each case asking for prints. But, even had we been aware that Sulzers were building such engines, and had we asked for and received their detail drawings, it is not to be assumed that we could have followed such drawings without modifications necessitated by our inability to obtain same materials used by them, the space and handling conditions to which we must conform, and the demands of the Bureau which is required to approve every detail. Moreover, as the responsibility and liability for the engines would lie with us, not with Sulzers, we would scarcely be justified in using their drawings without any analysis by our engineers. We are entirely ready to accept Sulzers' extensive experience and experimenting; but we are not prepared to blindly follow them in matters which are purely mechanical problems. In this connection, too, it is of interest to note that Sulzers have been going through a process of development:- for example, (1) The G-3 engines were built with separate cylinder heads;- for our 6-M-100 Sulzers advised and gave us drawings of cylinders with heads integral; - they have now reverted to loose heads, although of a design and arrangement differing from the G-3. (2) The G-3 crank-cases were built up of columns with cross-ties;- in July, 1914, Sulzers sent us suggestions for our type 6-M-100, in which they recommended a modification of the G-3 design, but still included the cross-ties; - in September, 1914, while Mr. Verhey was in Winterthur, they designed and recommended cast cylinder supports;- they now use a cast box crank-case. (3) The G-3 bedplates were cast with integral oil housings;- the same were shown on drawings laid out by Sulzers for our 6-M-100;- they now use cast bridges and frames, with sheet steel oil housings. (4) In 1914, Sulzers advised a definite sequence of the cranks;- they have now changed this sequence. (5) The G-3 was provided with a rotary scavenging pump valve;- in 1914 they recommended a piston valve, for the 6-M-100;- they now use automatic valves. (6) In 1914, they recommended poppet valves, for the cylinder scavenging;-

Transcript

COMPANY CORRESPONDENCE SUBJECT: TRANSACTIONS WITH SULZER BROS. [page 11] they now advise rotary valves (7) In 1914, they recommended, for the air coolers, air velocities about two and one half times as high as now, and cooling surfaces about forty per cent less than now. (8) In 1914, they recommended 10 per cent Nickel Steel Valve, set in cones, for the compressor; - they now use Chrome-nickel Steel Valves, with independent seats instead of cones. (9) They have found it necessary to materially increase the end clarances at piston ring joints. Were we to re-design any of the engines we have built, we would assuredly take advantage of drawings and advice from Sulzers; we would, also, have the time, which up to now has been lacking, to give more consideration to simplification, and reduction of cost of manufacture and assembly. Max Rotter V.P. in Chg. Engrg. MR

Details

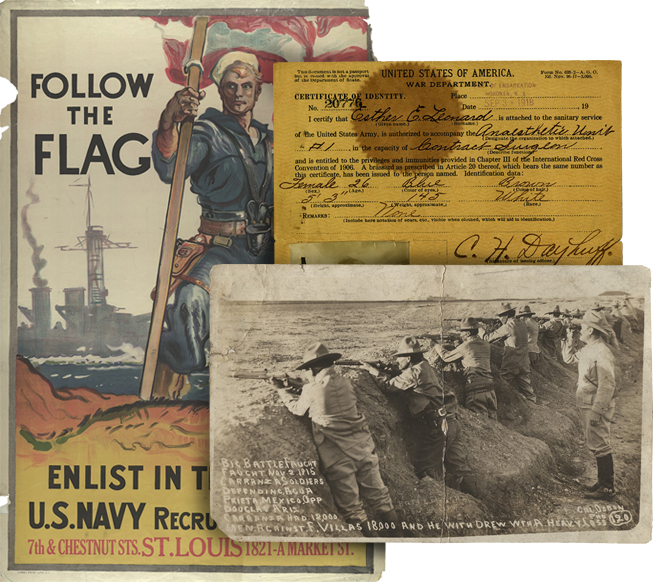

| Title | Max Rotter letter to James R. Harris - May 25, 1917 |

| Creator | Rotter, Max |

| Source | Rotter, Max. Letter to James R. Harris. 25 May 1917. Busch-Sulzer Collection. Wisconsin Historical Society, Madison, Wisconsin. |

| Description | Letter from Max Rotter, Vice President of Engineering, to James R. Harris, Vice-President and General Manager of the Busch-Sulzer Brothers Diesel Engine Company. Rotter outlines transactions with the Busch-Sulzer company and how their designs have been implemented in other engines. |

| Subject LCSH | Diesel engine; Submarine boats; Busch-Sulzer brothers Diesel engine company |

| Subject Local | WWI; World War I |

| Contributing Institution | Wisconsin Historical Society |

| Copy Request | Transmission or reproduction of items on these pages beyond that allowed by fair use requires the written permission of the Wisconsin Historical Society: 608-264-6535 |

| Rights | The text and images contained in this collection are intended for research and educational use only. Duplication of any of these images for commercial use without express written consent is expressly prohibited. |

| Date Original | May 25, 1917 |

| Language | English |